| Size of the Industry | Over 38, 00,000 Indian Weaving industries have been built throughout the country and more than 15, 00,000 domestic weaving industries |

| Geographical distribution | Chirala, Pedana, Polavaram, Mangalagiri, Pochamapali, Ponduru, Dharamvaram, Narayanpet, Puttapaka, Madhavaram, Emmiganur and Gadwal. |

History

History

The weavers' troubles in India began way back in 1995-1998 when the Deve Gowda government imposed a ban on Chinese silk yarn. The basic idea was that Varanasi saris would only be woven from silk yarn from Bangalore. Because of its superior quality, some weavers started smuggling Chinese yarn into the holy town. Realizing that their need for Chinese yarn would only grow, the weavers demanded an open general license. The Indian Weavers are its biggest asset and it is a marvel that an ancient art such as weaving still exist in our country, but the carriers of this tradition are the least respected lot in this nation. Weaving is skill that is done with utter brilliance which is usually passed on from generation to generation.

Throughout history there are evidences that show that weavers have always been a victim of a staunch hierarchical system in the country. Being at the bottom of the system they fall prey to the extreme forms of exploitation. Since the time of Kailas, weavers were the poorest of the lot, the British invasion and their policies of free trade further pushed them to the lowest strata of the society (economically). With the independence of India it was expected that the art of weaving would a get a refurbishment and that there would be an elevation in the status of weavers. However our government was not able to meet these expectations.

Brief introduction

Brief introduction

The Banarasi silk saris made in Varanasi are very much famous for centuries for their luxurious, intricately designed cloth. These were a must have for all Indian weddings. More than 600,000 weavers live in Varanasi and nearby districts, weaving mainly for the domestic market. During 1990's, the silk handloom weavers who make the Banarasi saris have seen their fortunes vanish. Trade liberalization is been the driving force of economic globalization, pursued relentlessly by rich nations and international financial institutions at the expense of the poor of the world.

Brocade weaving, especially with gold and silver, has been an age-old tradition in India. There are two broad classes of brocades. Brocades of pure silk or silk and cotton blends and zari brocades with gold and silver threads. The most important material in brocade weaving is silk. It facilitates lovely weaves, is durable, strong, fine and smooth. There are several varieties of raw silk of which the chief ones used for brocades are Tanduri, Banaka and Mukta. Tanduri is imported from Malda and other places in Bengal. Banaka is thinner and finer variety and is mostly used to weave soft fabrics such as turbans and handkerchiefs. Mukta is a coarse and durable silk used for kimkhabs, a fine silk would not withstand heavy gold patterns.

Size of the industry

Size of the industry

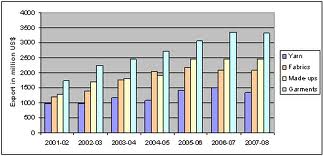

Domestic and Export Share

Domestic and Export Share

Top leading Companies

Top leading Companies

Some leading Indian companies engaged in the India weaving industry are:

- Jai India Weaving Mills Private Limited: Dealing with manufacturing and exporting of weaving products.

- Vardhaman Spinning: Manufacturer and exporter of weaving products

- Arvind Mills: Manufactures and trades weaving products

- Advance Syntex Pvt. Ltd.: Manufacturer of weaving products

Employment opportunities

Employment opportunities

Latest developments

Latest developments

- It is estimated that the Indian Weaving Industry would grow by 25% to over 35 million tons by the year 2010. The Indian weaving industry will maintain its growth throughout 2010. Apparel being the mostly used woven products is expected to expand its market in the international arena as well.

- According to the silk weaving industry a combination of the abolition of quantitative restrictions, declining tariffs on textile imports, and events like the opening of the Nathu La Pass are resulting in cheap imports of silk, especially from China, which is posing serious competition to the Indian silk-weaving industry.

Recent Press Release

Recent Press Release

INDIAN weaving industry AT A Glance IN 2020 - 2021

INDIAN weaving industry AT A Glance IN 2020 - 2021

INDIAN weaving industry AT A Glance IN 2019 - 2020

INDIAN weaving industry AT A Glance IN 2019 - 2020

INDIAN weaving industry AT A Glance IN 2018 - 2019

INDIAN weaving industry AT A Glance IN 2018 - 2019

INDIAN weaving industry AT A Glance IN 2017 - 2018

INDIAN weaving industry AT A Glance IN 2017 - 2018

INDIAN weaving industry AT A Glance IN 2015 - 2016

INDIAN weaving industry AT A Glance IN 2015 - 2016

INDIAN weaving industry AT A Glance IN 2011 - 2012

INDIAN weaving industry AT A Glance IN 2011 - 2012

Indian Industries

INDIAN WEAVING INDUSTRY

INDIAN WEAVING INDUSTRY